Automation for Hydrogen Projects in the Shortest Possible Time

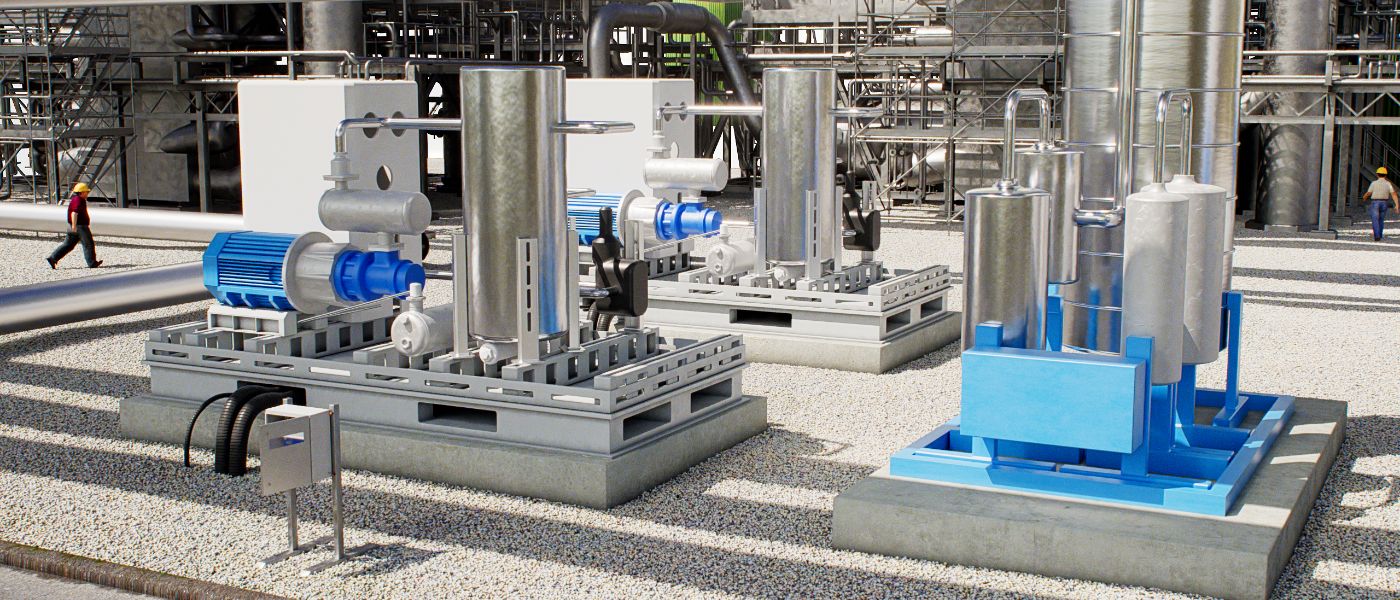

The hydrogen infrastructure must be massively expanded in the coming years – be it in the provision of electrolyzers and other plants for hydrogen production, pipelines and ships for hydrogen transport, tanks and other storage technologies, or fuel cells and other plants for using hydrogen.

Turck automation solutions bring your hydrogen projects faster to the market. Turck has decades of experience in the automation of comparable plants with LNG, natural gas and other explosive gases.

With this experience and the right automation concept, we can implement your hydrogen project faster than other suppliers. The project experience of our experts plays a decisive role in this. Choosing the right automation solution is crucial to avoid lengthy commissioning or costly troubleshooting in the final phase of a project, and thus to get to market faster.

Hydrogen exists in the universe since 13 billion years, but now time is running, as the simplest and most abundant molecule in the universe is set to become a mainstay of the future energy supply. Before you waste any more time: Automate your hydrogen projects with Turck.

These Solutions Reduce Your Time-to-Market

It's often the little things that end up delaying projects. The following solutions enable your hydrogen project to take the fastest route.

Webinar: Time-to-Market Hydrogen

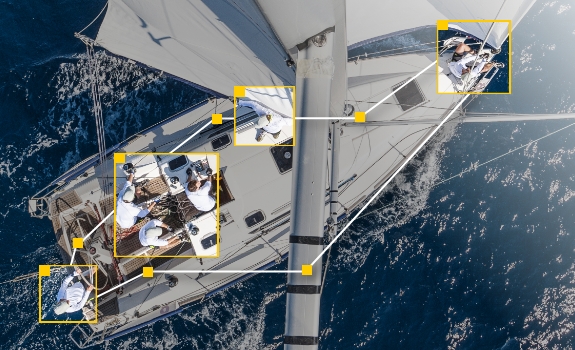

These Projects Prove: Turck Can Do Hydrogen

Thanks to decades of experience with process automation in explosion-proof areas, we are able to automate your hydrogen project quickly and efficiently right from the start. Convince yourself.

Improve your Sustainability Balance through Automation

Even beyond H2 projects, automation can make your production more efficient and energy-saving. Learn more about the solutions we can support you with on our sustainability topic page.

Products for the Hydrogen Infrastructure

These products and systems get your hydrogen project faster to market

IP67 I/O modules – also for Zone 2

Turck's I/O modules with multiprotocol Ethernet, combined with special protective housings, can also be used in Ex Zone 2. They also offer logic control functions as a standard feature. This simplifies modular and scalable plant concepts and reduces the load on the controller.

Condition monitoring for control cabinets

With three on-board sensors, Turck's slimline 12 or 18 mm control cabinet guards monitor temperature, humidity and door gap. The IM18-CCM series, with an open Linux platform or user-friendly siineos operating system, also allows external sensors to be connected and transmits measured values to the IT world via Ethernet.

Safety modules with integrated safety controller

IP67 block I/Os enable cabinet-free safety functions. Safety controllers enable safety applications to be tested offline and controlled remotely in live operation.

Edge controller and decentralized logic

Turck offers one of the most diverse portfolios of edge controllers, i.e.: controllers with a cloud connection, with or without display. Our I/O solutions – with IP20 or IP67 protection – also bring logic to the field and thus replace or relieve the PLC – even in Ex Zone 2.

Ethernet in Ex areas

Ethernet is only gradually gaining acceptance in Ex areas. Our technology page explains the reasons for this and how you can use Ethernet today in hazardous areas for digital process optimization.

Isolators and barriers

Our interface technology devices for the galvanic isolation of signals from the hazardous area offer the highest signal density on the market. Devices for safe areas as well as compact devices for small control boxes complete the range.

Ask an Expert

If you have any questions about our hydrogen solutions or about a specific device, simply use or contact form. Our experts will be pleased to help you.

Jan Gubini