Cloud Solutions Facilitate the Replacement of IO-Link Devices

Bidirectional transfer of additional data supports maintenance engineers when setting up new IO-Link devices

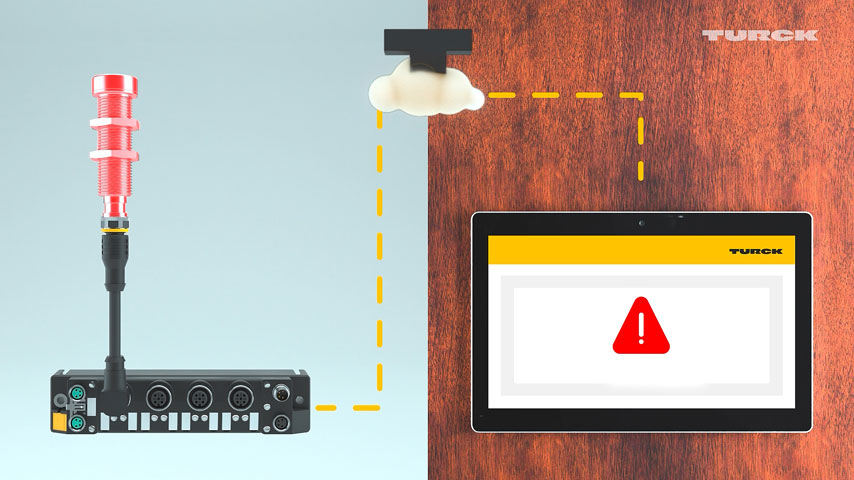

Replacing a faulty field device often creates a huge amount of work for maintenance engineers. If a sensor is found to be the cause of a fault, the replacement device must be commissioned with the correct parameters and identification data as soon as possible. To simplify this process, Turck Cloud Solutions enable information to be exchanged effectively between the field device and the cloud system via IO-Link.

Your Benefits

- Reduced machine downtime thanks to rapid device replacement

- Optimized connection of various IT and OT systems via the cloud

- Improved transparency of plant processes

- Extended functionality via ERP and MES connections or a "digital shadow"

IO-Link communication increases information volumes

In addition to cyclic process data, IO-Link devices transfer device data. Sensors provide a wide range of data, such as operating hours counters, error memory or process quality indicators. They also transfer parameters, diagnostic data and a device description with information such as the ID number, function or manufacturer. This information can be transferred by an IO-Link master and eventually uploaded to the cloud.

Industrial cloud transfers device data to the field

Turck Cloud Solutions provides users with an online interface that visualizes machine data and offers various options for setting features like alarms. The cloud also functions as a storage location that can be accessed as required. Additional IO-Link data can be stored here such that, during a device replacement, the cloud can send the data back to the field via the same infrastructure from which it received the data. This feature considerably reduces the amount of work required for maintenance engineers to set up the new device, and is made possible by continuous, bidirectional communication.

Simulate plant processes in a digital twin

Users will quickly realize how much extra functionality becomes available once they connect the cloud to an ERP system or MES. This functionality includes the ability to automatically order replacement devices or stop and restart machines remotely.

Furthermore, data can be transferred to a digital twin or virtual machine image in order to better understand plant processes and the behavior of field devices. Users can then use the results from this testing and learning environment to optimize the processes of real machines.

Select Country

Turck worldwide